Model: CS-G8807L

Addtime: 2019.01.18

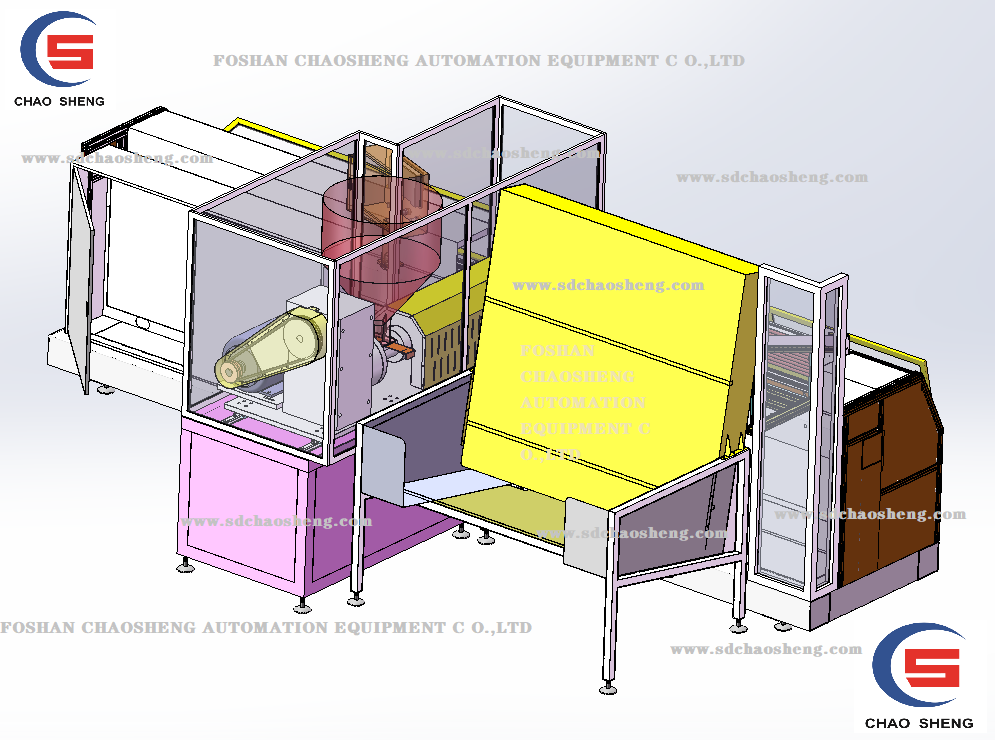

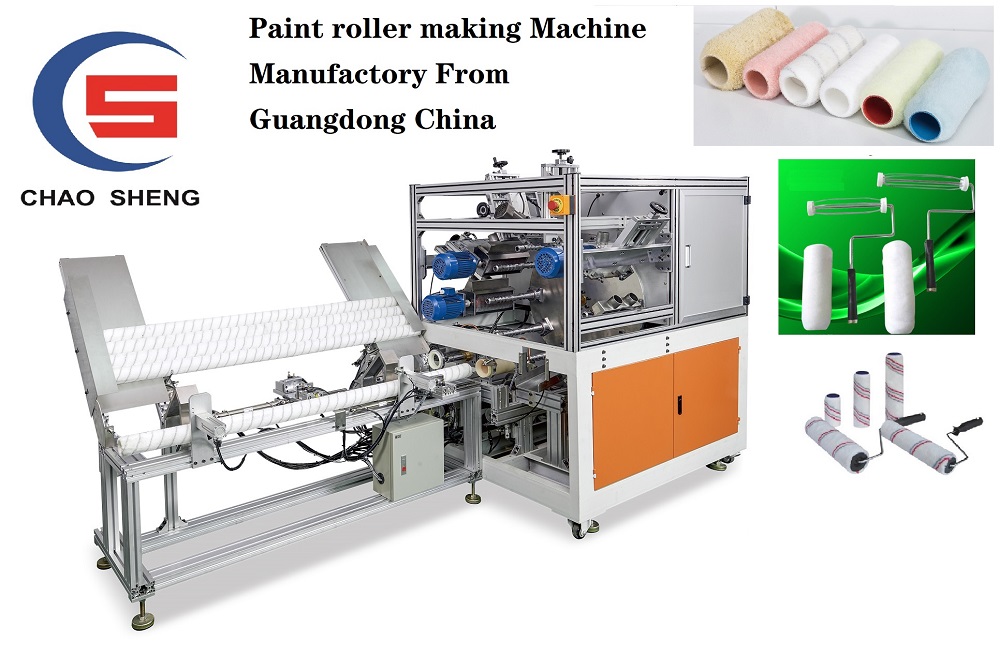

CS-G8807L Automatic end cap install and combing machine for mini paint rollers

PRODUCT FEATURES / FUNCTIONS

Automatic end cap install and combing machine for mini paint rollers is adopted the advancedautomation design idea at present.Controlled by Electric integrated design PLC programming and Process parameters of various products in the operating Interface of the system Touch screen Flexible setting, real-time

monitoring of each action in operation, automatic detection of incoming machine sensors for assembly and processing, automatic stop alarm warning of abnormal action faults, convenient maintenance and processing.

The integrated function of automatic incoming inspection direction, automatic sub-direction,automatic pressing and combing for small wool sets can save customers manual to speed up production cycle and reduce production and use sites.The length specification can be adjusted for 2 "4" 6 inch.

****The equipment is equipped with conveyor belt, which can be combined with the previous process to form an automatic production line.

|

Specification |

|

|

Overal size (L*W*H) |

2600*1400*1300mm |

|

G.W |

800kg |

|

Voltage |

AC220V / 50Hz |

|

Power |

2KW |

|

air consumption |

1.5m3/hour( 0.5~0.8Mpa air presure) |

|

Capacity |

1200pcs/ hour |

|

Suitable Diameter of paint roller |

15mm

|

|

suitable length of paint roller

|

2 inch ; 4 inch; 6 inch |

More running video links on youtube, pls click below:

CS-G8807L Automatic end cap install and combing machine for mini paint rollers

PRODUCT FEATURES / FUNCTIONS

Automatic end cap install and combing machine for mini paint rollers is adopted the advancedautomation design idea at present.Controlled by Electric integrated design PLC programming and Process parameters of various products in the operating Interface of the system Touch screen Flexible setting, real-time

monitoring of each action in operation, automatic detection of incoming machine sensors for assembly and processing, automatic stop alarm warning of abnormal action faults, convenient maintenance and processing.

The integrated function of automatic incoming inspection direction, automatic sub-direction,automatic pressing and combing for small wool sets can save customers manual to speed up production cycle and reduce production and use sites.The length specification can be adjusted for 2 "4" 6 inch.

****The equipment is equipped with conveyor belt, which can be combined with the previous process to form an automatic production line.

|

Specification |

|

|

Overal size (L*W*H) |

2600*1400*1300mm |

|

G.W |

800kg |

|

Voltage |

AC220V / 50Hz |

|

Power |

2KW |

|

air consumption |

1.5m3/hour( 0.5~0.8Mpa air presure) |

|

Capacity |

1200pcs/ hour |

|

Suitable Diameter of paint roller |

15mm

|

|

suitable length of paint roller

|

2 inch ; 4 inch; 6 inch |

More running video links on youtube, pls click below:

中文版

中文版