Model: CS-G8804L

Addtime: 2019.01.18

PRODUCT FEATURES / FUNCTIONS

4th Generation with better performance and more stable .

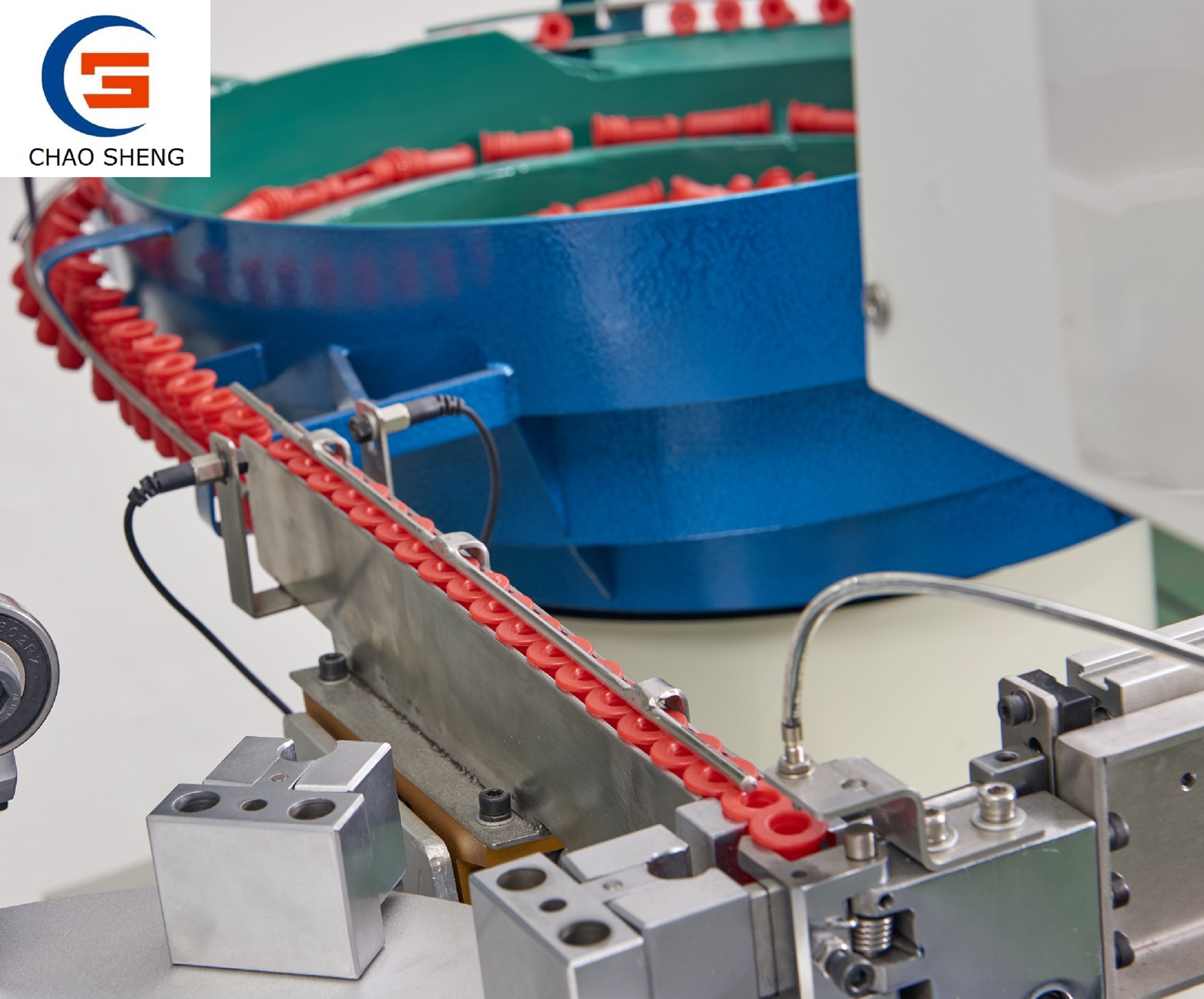

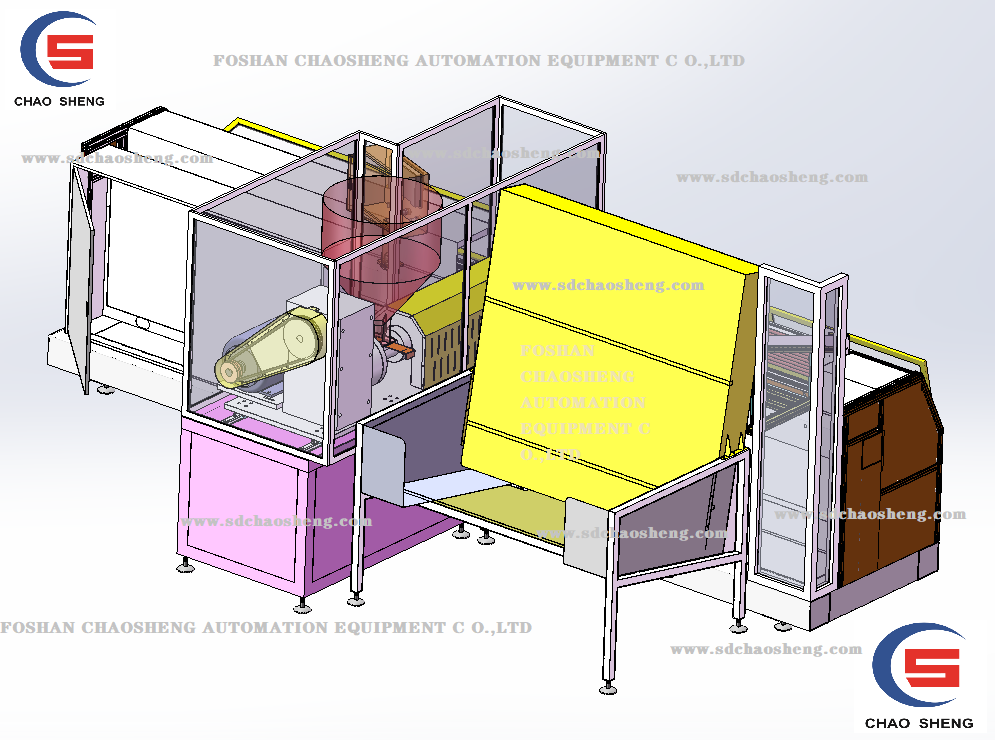

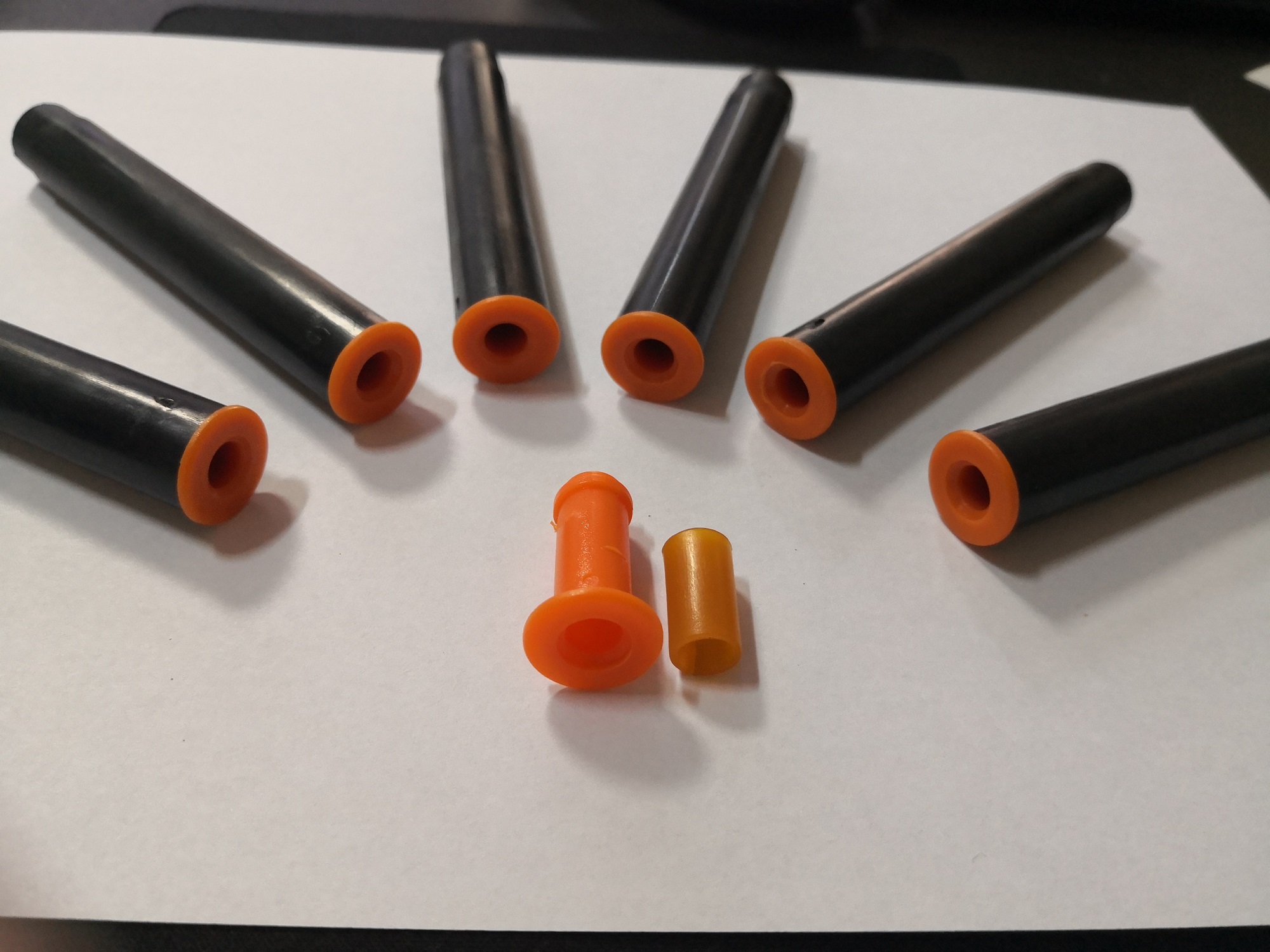

Chaosheng Automatic end cap bearing inserting machine for mini roller ,CS-G8804L ,adopted the advanced automation design idea at present. Controlled by Electric integrated design PLC programming and Process parameters of various products in the operating Interface of the system Touch screen Flexible setting, real-time monitoring of each action in operation, automatic detection of incoming machine sensors for assembly and processing, automatic stop alarm warning of abnormal action faults, convenient maintenance and processing. The rubber plug is arranged in the direction automatically, the clamp is fed automatically, the splitter is positioned in 8 positions, the rubber plug is positioned and the guide is fixed, the clamp leak is detected, the clamp leakage is eliminated automatically, which saves the customer labor. General customized Small paint roller caps.

|

Specification |

|

|

Oversize: L*W*H |

1300*1000*1300mm |

|

GW: |

350kgs |

|

Voltage: |

AC220V / 50Hz |

|

Power: |

1.5KW |

|

Air consumptioin: |

1.2m3/H( 0.5~0.8Mpa Air pressure) |

|

Production Capacity: |

2400pcs/Hour |

|

suitable dia.of mini paint roller:

|

15mm~30mm (one dia use one machine) |

More running video links on youtube ,please click below:

PRODUCT FEATURES / FUNCTIONS

4th Generation with better performance and more stable .

Chaosheng Automatic end cap bearing inserting machine for mini roller ,CS-G8804L ,adopted the advanced automation design idea at present. Controlled by Electric integrated design PLC programming and Process parameters of various products in the operating Interface of the system Touch screen Flexible setting, real-time monitoring of each action in operation, automatic detection of incoming machine sensors for assembly and processing, automatic stop alarm warning of abnormal action faults, convenient maintenance and processing. The rubber plug is arranged in the direction automatically, the clamp is fed automatically, the splitter is positioned in 8 positions, the rubber plug is positioned and the guide is fixed, the clamp leak is detected, the clamp leakage is eliminated automatically, which saves the customer labor. General customized Small paint roller caps.

|

Specification |

|

|

Oversize: L*W*H |

1300*1000*1300mm |

|

GW: |

350kgs |

|

Voltage: |

AC220V / 50Hz |

|

Power: |

1.5KW |

|

Air consumptioin: |

1.2m3/H( 0.5~0.8Mpa Air pressure) |

|

Production Capacity: |

2400pcs/Hour |

|

suitable dia.of mini paint roller:

|

15mm~30mm (one dia use one machine) |

More running video links on youtube ,please click below:

中文版

中文版