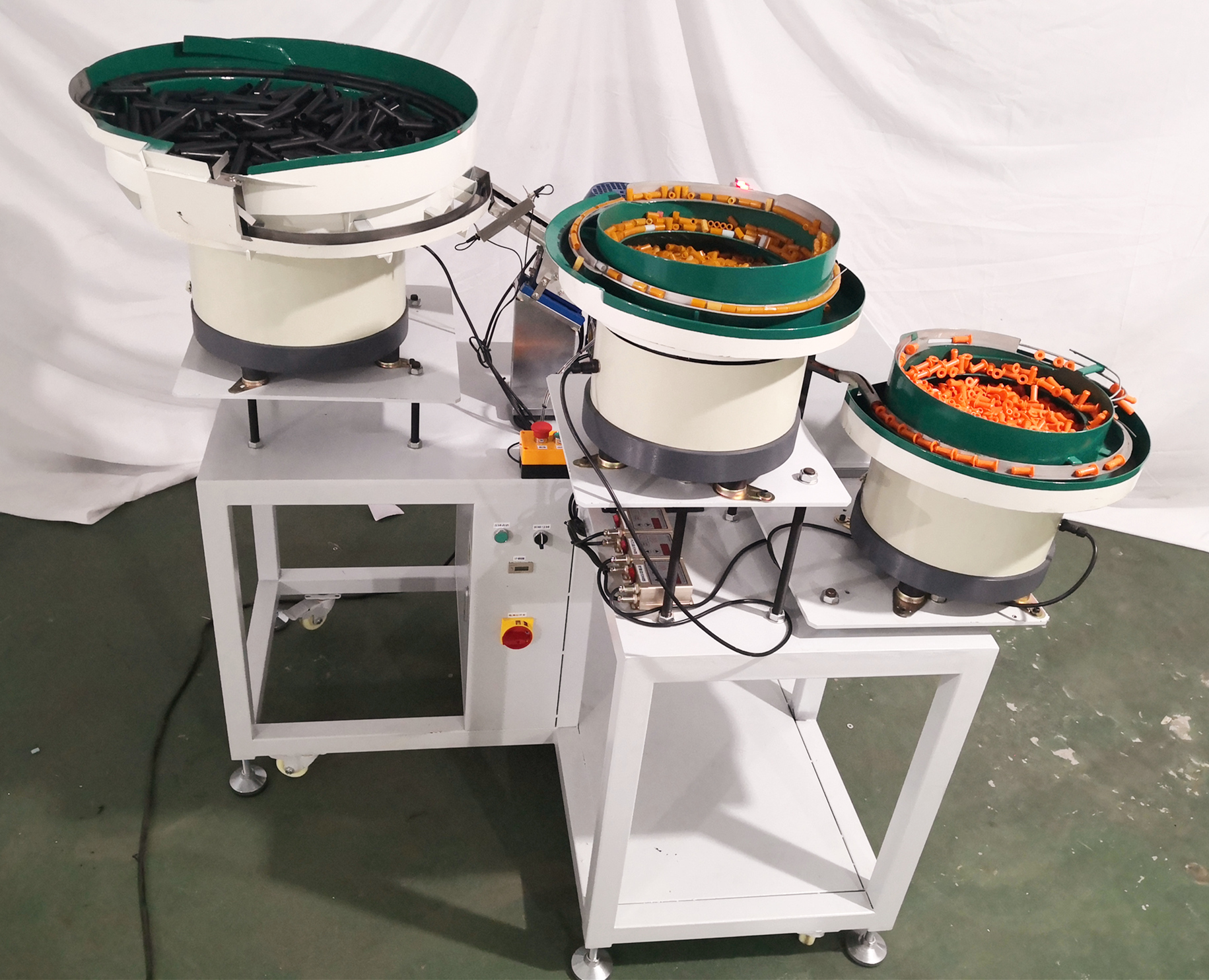

Model: CS-G8824L

Addtime: 2020.09.22

|

Item No.: |

CS-G8824L |

|

Description: |

|

|

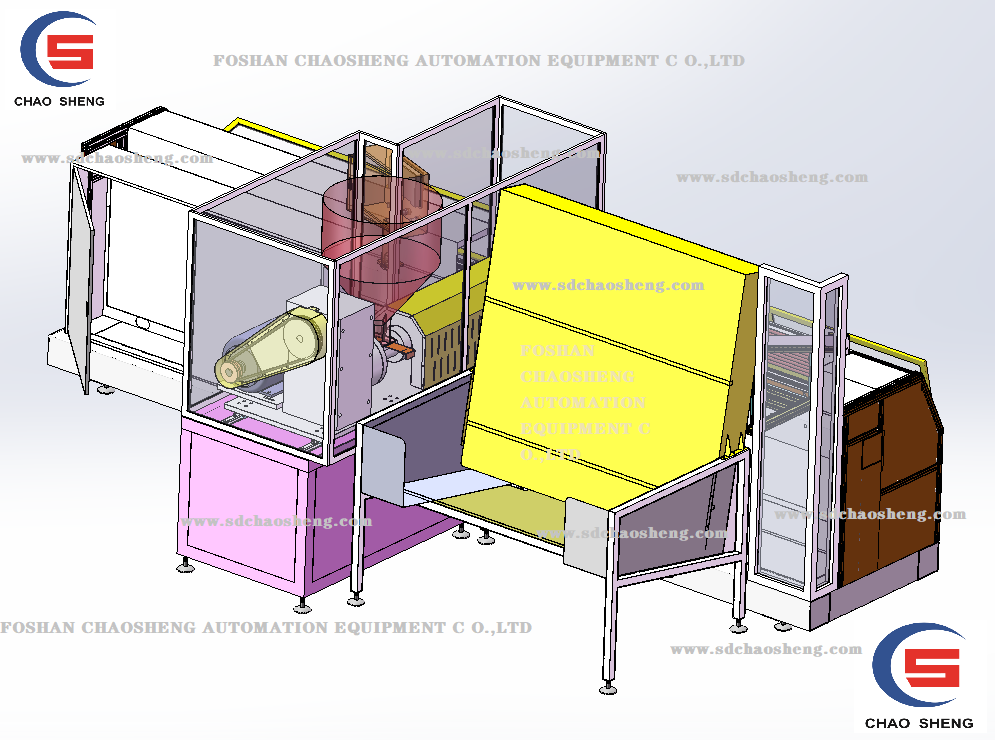

Oversize:L*W*D |

1300*1400*1500mm |

|

Total W. |

? 800kgs |

|

Voltage |

380v |

|

Total Power: |

2KW |

|

Air consumption: |

0 |

|

Capacity: |

more than 2400pcs?/hour |

|

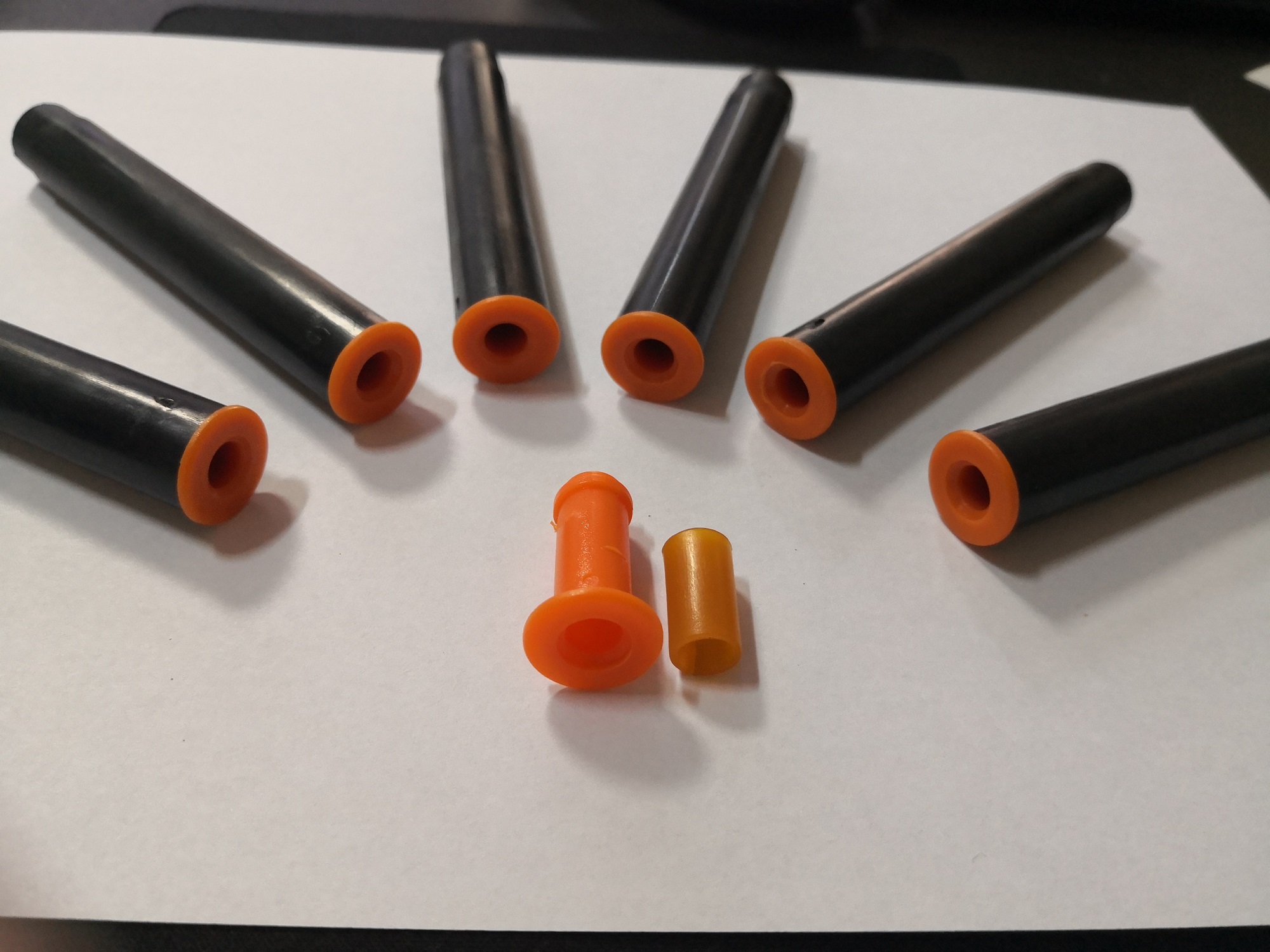

workable tube diameter: |

15mm or 30mm? (one diamter one machine) |

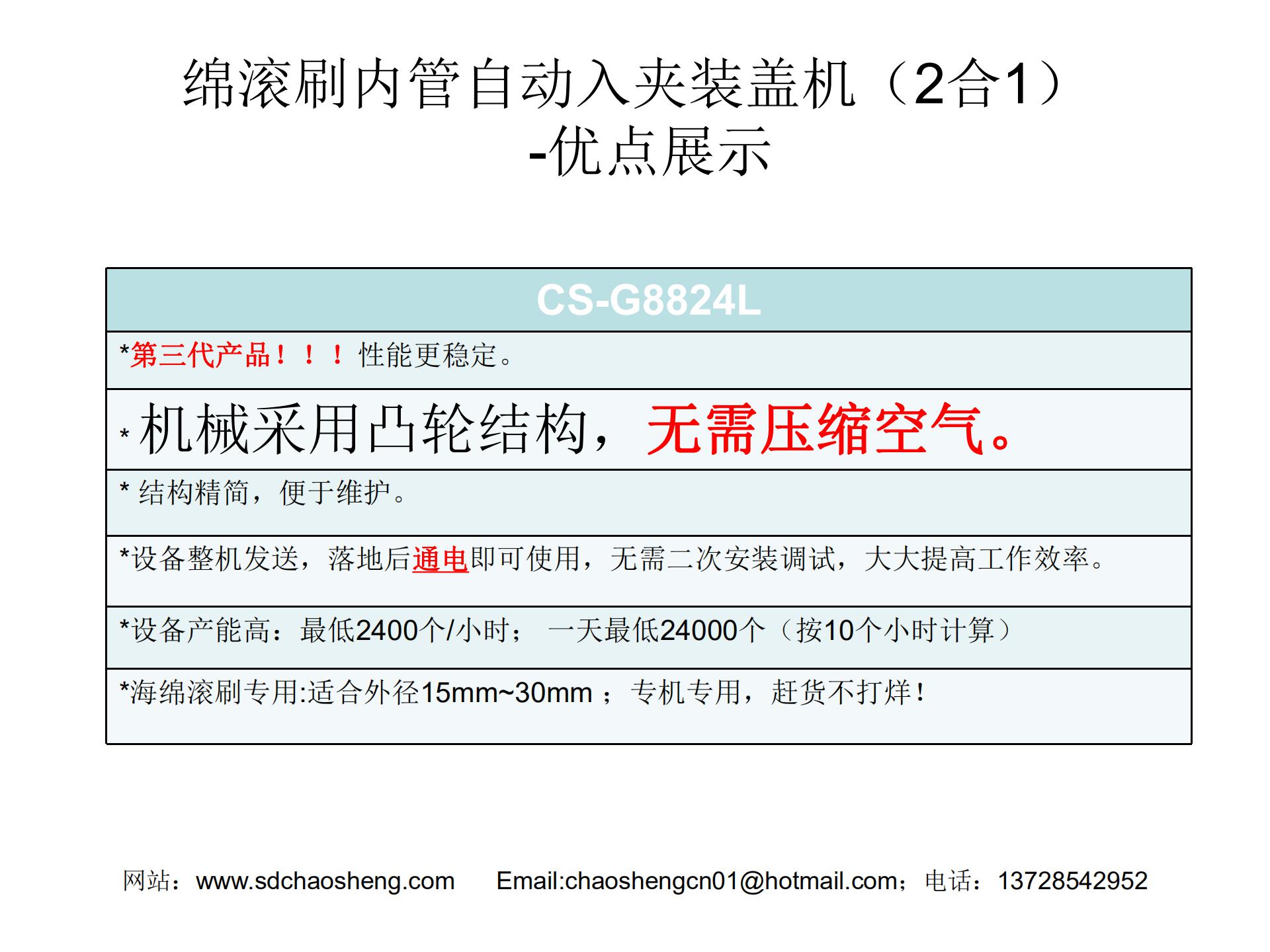

Advantages show:

* Third generation product!!Performance is more stable.

* Mechanical use of CAM structure, no need? compressed air.

* Streamlined structure for easy maintenance.

* The machine delivereied in intergrally, and can be used after power connecting, without the need of second installation and debugging, which greatly improves the work efficiency.

* The device is equipped with a detector at the loading cover, which can detect whether the pipe has been installed with the inner clip. If not, the loading action of the cover will be suspended until the inner clip is installed automatically.The feared risk of missing in-clamp assembly has been circumvented here.

* High equipment capacity: minimum 2400 hours;Minimum of 24,000 units per day (based on 10 hours)

* Special for sponge roller brush: suitable for 15mm~30mm outside diameter ;

Vedio running link:http://https://youtu.be/FboUEe6tPvA

|

Item No.: |

CS-G8824L |

|

Description: |

|

|

Oversize:L*W*D |

1300*1400*1500mm |

|

Total W. |

? 800kgs |

|

Voltage |

380v |

|

Total Power: |

2KW |

|

Air consumption: |

0 |

|

Capacity: |

more than 2400pcs?/hour |

|

workable tube diameter: |

15mm or 30mm? (one diamter one machine) |

Advantages show:

* Third generation product!!Performance is more stable.

* Mechanical use of CAM structure, no need? compressed air.

* Streamlined structure for easy maintenance.

* The machine delivereied in intergrally, and can be used after power connecting, without the need of second installation and debugging, which greatly improves the work efficiency.

* The device is equipped with a detector at the loading cover, which can detect whether the pipe has been installed with the inner clip. If not, the loading action of the cover will be suspended until the inner clip is installed automatically.The feared risk of missing in-clamp assembly has been circumvented here.

* High equipment capacity: minimum 2400 hours;Minimum of 24,000 units per day (based on 10 hours)

* Special for sponge roller brush: suitable for 15mm~30mm outside diameter ;

Vedio running link:http://https://youtu.be/FboUEe6tPvA

中文版

中文版