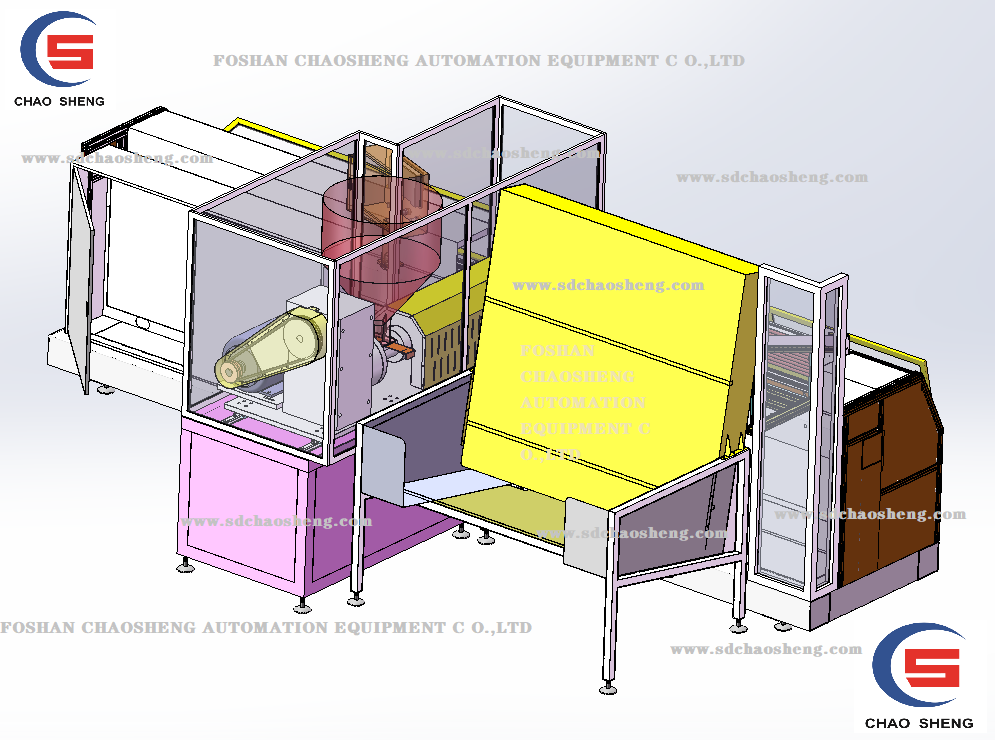

Model: CS-G8806L

Addtime: 2019.01.18

CS-G8806L

Automatic End cap assembly machine for big paint roller is adopted the advanced automation design idea at present.

Controlled by Electric integrated design PLC programming and Process parameters of various products in the operating Interface of the system Touch screen.Flexible setting, real-time monitoring of each action in operation, automatic detection of incoming machine sensors for assembly and processing, automatic stop alarm warning of abnormal action faults, convenient maintenance and processing.

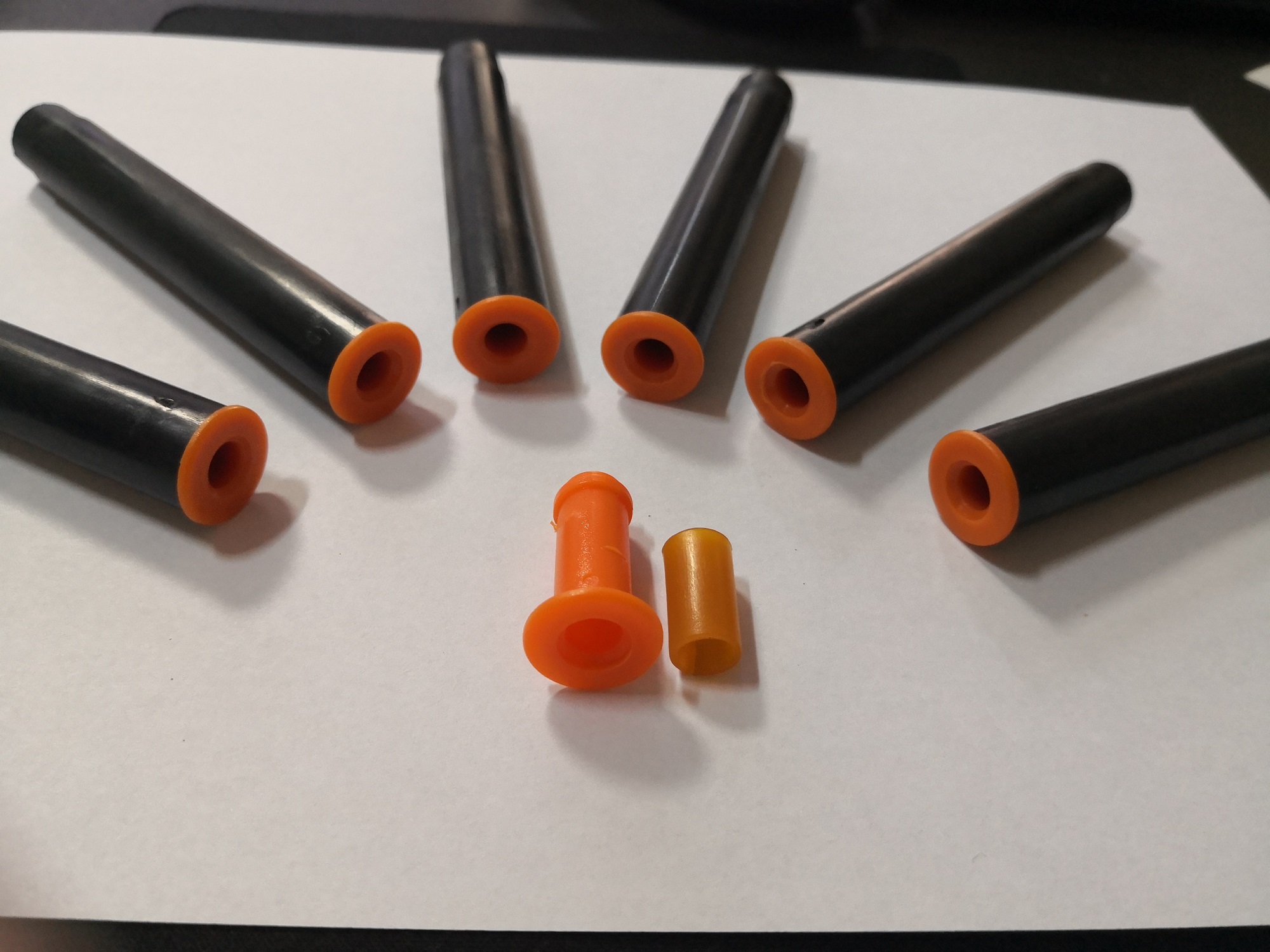

The end cap is automatically loaded, the inner tube is automatically loaded, the wool sleeve is automatically loaded, and the other end cover is automatically loaded in.The end cap is pressed in place, automatic discharge, save labor for the customer, reduce the production cycle time, reduce the production and use of the site.

The length specification can be adjusted to 7 inch ~ 10 inch. 38mm and 44mm tube can be used. Prior to the operation of the automatic machine line use is better.

It is with conveyor belt which can combine with our CS-G8803L (6 in 1 multi-function machine) to form a full automatic production line.It also can combine with your last procession to form a production line.

|

Specification: |

|

|

Oversize: L*W*H |

3000*2800*1600mm |

|

N.W: |

900kgs |

|

Voltage |

Voltage AC220V / 50Hz |

|

Power |

2.5KWKW |

|

Air comsumption |

2.5m3/hour( 0.5~0.8Mpa air pressure) |

|

Capacity |

800pcs/hour |

|

workable paint roller length

|

from 7 inch~10 inch |

|

workable paint roller dia.:

|

38mm &44mm |

More video links pls press below:

CS-G8806L

Automatic End cap assembly machine for big paint roller is adopted the advanced automation design idea at present.

Controlled by Electric integrated design PLC programming and Process parameters of various products in the operating Interface of the system Touch screen.Flexible setting, real-time monitoring of each action in operation, automatic detection of incoming machine sensors for assembly and processing, automatic stop alarm warning of abnormal action faults, convenient maintenance and processing.

The end cap is automatically loaded, the inner tube is automatically loaded, the wool sleeve is automatically loaded, and the other end cover is automatically loaded in.The end cap is pressed in place, automatic discharge, save labor for the customer, reduce the production cycle time, reduce the production and use of the site.

The length specification can be adjusted to 7 inch ~ 10 inch. 38mm and 44mm tube can be used. Prior to the operation of the automatic machine line use is better.

It is with conveyor belt which can combine with our CS-G8803L (6 in 1 multi-function machine) to form a full automatic production line.It also can combine with your last procession to form a production line.

|

Specification: |

|

|

Oversize: L*W*H |

3000*2800*1600mm |

|

N.W: |

900kgs |

|

Voltage |

Voltage AC220V / 50Hz |

|

Power |

2.5KWKW |

|

Air comsumption |

2.5m3/hour( 0.5~0.8Mpa air pressure) |

|

Capacity |

800pcs/hour |

|

workable paint roller length

|

from 7 inch~10 inch |

|

workable paint roller dia.:

|

38mm &44mm |

More video links pls press below:

中文版

中文版